NORCAR a60E1 Power+ WHEELED MINILOADER

The Norcar a60E1 gives you top performance, minimal vibrations, zero emissions and an extremely low noise level. The electric miniloader require very low maintenance and service, it is also fun, easy and safe to use. Since the miniloader is emission-free it benefits the environment, people and animals. This provides great benefits for you and your business.

Norcar a60E1 is perfect for work in sound-sensitive environments with high standards of cleanliness, both indoors and outdoors. Therefore it is well suited for work in horse stables, on farms, on construction sites, in parks and for property maintenance.

The miniloader's lithium battery is simply charged with a standard Type 2-connector at home, at the work site or at charging stations.

Updated with Power+

I

Increased lifting power

The machines can now handle heavier loads and more demanding tasks,making them ideal for various applications.

Stronger boom construction

The reinforced boom construction provides increased durability and reliability,allowing the machines to endure more intensive and prolonged use withoutcompromising performance or safety

Expansion of work areas

With the improved specifications in the Power+ Edition, Norcar machines cannow be used in even more work environments and applications. The increasedversatility makes them a valuable tool for both small and large projects, fromconstruction sites to agriculture and green space maintenance.

Turning Radius

Loading Height

Tipping Load

| +extra weight 180kg | ||||

|---|---|---|---|---|

| Straight | Articulated | Straight | Articulated | |

| A. Transport position, kg | 1300 | 650 | 1300* | 940 |

| B. Boom horizontal, kg | 1250 | 790 | 1650 | 1040 |

| C. Boom horizontal, kg | 850 | 500 | 1100 | 690 |

| D. Boom horizontal+ extension, kg | 690 | 420 | 930 | 520 |

| E. Boom horizontal + extension kgal, kg | 550 | 300 | 730 | 460 |

| *Limited by Hydraulic |

Specifications

| Engine | |

|---|---|

| Driveline Motor | Interior Permanent Magnet (IPM) |

| Driveline power (peak) | 9,9/13.3 (kW/hp) |

| Work hydraulic | Interior Permanent Magnet (IPM) |

| Work hydraulic power (peak) | 5/6,7 (kW/hp) |

| Power | |

|---|---|

| Gross power (kW/hp) | 10 |

| Max gross torque (Nm) | 90 |

| Max engine speed without load (r/min) | 6000 |

| Electrical System | |

|---|---|

| Battery type | Lithium-Ion (LFP |

| Battery Voltage (V) | 48 |

| Battery capacity (kWh) | 11,6 |

| Battery capacity (Ah) | 240 |

| Indicative runtime (hours) | ~8 |

| Onboard charging time 230 VAC 16A (hours) | ~5 |

| Auxiliary Battery Voltage (V) | 12 |

| Auxiliary Battery capacity (Ah) | 12 |

| Auxiliary power output max (W) | 500 |

| Service Volumes | |

|---|---|

| Hydraulic tank (l) | 50 |

| Hydraulic system total volume (l) | 55 |

| Performance | |

|---|---|

| Breakout force 50cm (kg) ISO14397-2 | 960 |

| Tipping Load, straightkg) | 960 |

| Tipping Load, articulated (kg) ISO14397-1 | 1150 |

| Operating weight (kg) | 1470 |

| Drive speed (km/h) | 11 |

| Pulling weight high (kg) | 925 |

| Working hydraulic (l/min) | 33 |

Norcar Drive System

The direction of travel is selected by a button on the loader’s control stick.

With the Automotive drive system, the engine’s RPM can also be adjusted by a hand gas throttle, allowing for an efficient use of hydraulic equipment, such as lawn mowers.

The loader’s driving speed and the engine’s RPM are regulated by a gas pedal operated with the right foot.

At your left foot, there is a combined brake and clutch that allows you manually to reduce the driving speed, even at a high RPM, e.g., during loading work or when using equipment requiring a high engine RPM.

The drive system is easy to run and is excellent for loading, as well as for more continuous driving along roads and streets. Operating the system can be likened to driving a car with an automatic transmission.

Standard equipment

- Work lights LED, front

- Electrically maneuvered parking brake/safety system

- Float on the lifting boom

- Hand throttle/Foot throttle

- Multifunctional display

- Type 2 charger connector

- Suspension seat with armrests, seatbelt

- Adjustable steering column

- Hydraulic oil cooler

- Telescope Extension Boom, 600 mm

- MultiFaster Quick release coupling

- Roll cage ROPS/FOPS

- Traction control

- Automotive drive system

Optional Extras

Tires

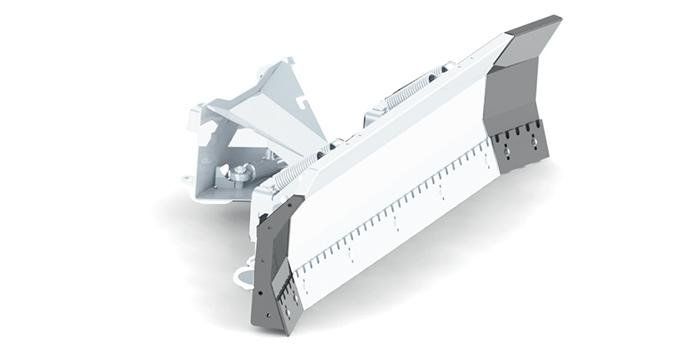

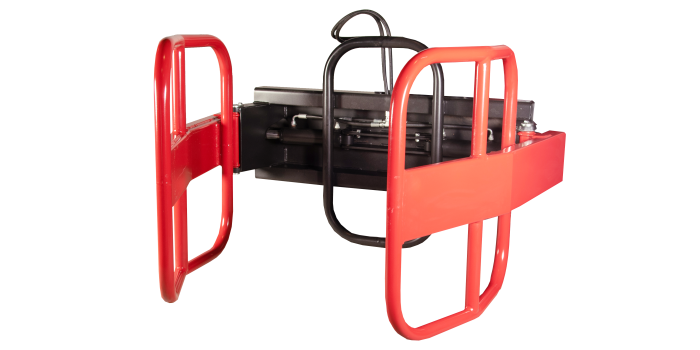

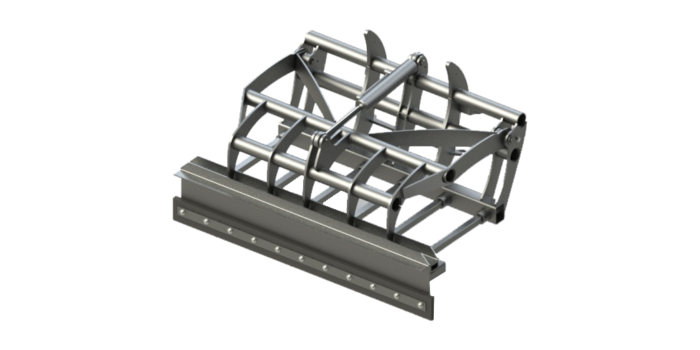

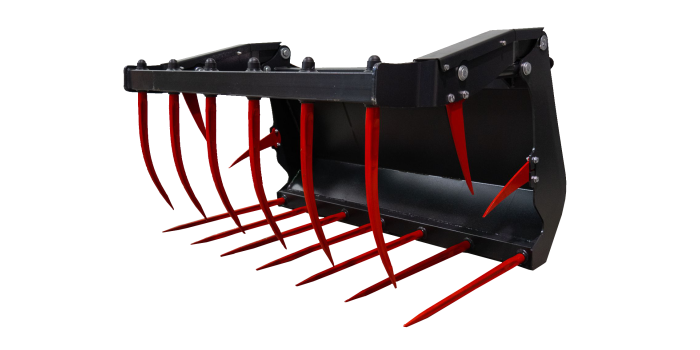

Tools - Very Compatible

Tools - Compatible

NORCAR a60E1 photos