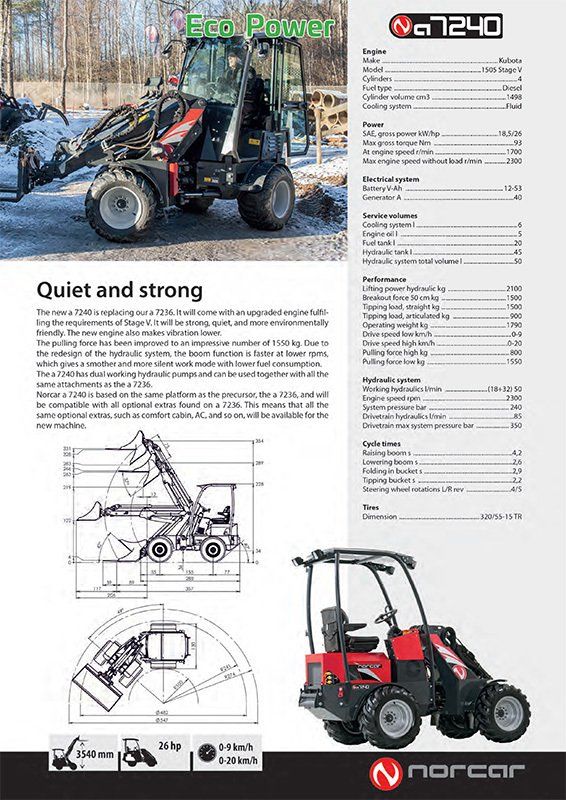

NORCAR a7240 WHEELED Power+ MINILOADER

Upgraded to Power+ Edition – Stronger lifting boom and increased lifting power, now handling up to 1800 kg on a pallet.

The a7240, a powerful machine with great ground clearance and high specifications as standard. The four-cylinder diesel engine and dual working hydraulic pumps provides a machine that is well equipped for a wide selection of attachments in different working situations. Multiple functions can be used simultaneously without interfering with each other, making work more efficient. The pulling force goes up to an impressive number of 1550 kg. Due to the design of the hydraulic system, the boom function is fast even at lower rpms, which provides a smoother and more silent work mode with a lower fuel consumption.

Updated with Power+

I

Increased lifting power

The machines can now handle heavier loads and more demanding tasks,making them ideal for various applications.

Stronger boom construction

The reinforced boom construction provides increased durability and reliability,allowing the machines to endure more intensive and prolonged use withoutcompromising performance or safety

Expansion of work areas

With the improved specifications in the Power+ Edition, Norcar machines cannow be used in even more work environments and applications. The increasedversatility makes them a valuable tool for both small and large projects, fromconstruction sites to agriculture and green space maintenance.

Turning Radius

Loading Height

Tipping Load

| Tipping load | +extra weight 340kg | |||

|---|---|---|---|---|

| Tipping load with pallet fork | Straight | Articulated | Straight | Articulated |

| A. Transport position, kg | 1650 | 1200 | 2050* | 1600 |

| B. Boom horizontal, kg | 1580 | 1150 | 2270 | 1600 |

| C. Boom horizontal, kg | 1100 | 820 | 1690 | 1190 |

| D. Boom horizontal+ extension, kg | 810 | 570 | 1280 | 860 |

| E. Boom horizontal + extension kgal, kg | 670 | 480 | 1040 | 700 |

| *Limited by hydraulic |

Specifications

| Engine | |

|---|---|

| Make | Kubota |

| Model | 1505 Stage V |

| Cylinders | 4 |

| Fuel type | Diesel |

| Cylinder volume (cm³) | 1498 |

| Cooling system | Fluid |

| Power | |

|---|---|

| SAE, gross power (kW/hp) | 18,5/26 |

| Max gross torque (Nm) | 93 |

| At engine speed (r/min) | 1700 |

| Max engine speed without load (r/min) | 2300 |

| Electrical System | |

|---|---|

| Battery (V-Ah) | 12 - 53 |

| Generator (A) | 40 |

| Service Volumes | |

|---|---|

| Cooling System (l) | 6 |

| Engine Oil (l) | 5 |

| Fuel Tank (l) | 20 |

| Hydraulic Tank (l) | 45 |

| Hydraulic System Total Volume | 50 |

| Performance | |

|---|---|

| Lifting Power Hydraulic (kg) | 2150 |

| Breakout force 50cm (kg) | 1500 |

| Tipping load, straight (kg) | 1500 |

| Tipping load, articulated (kg) | 900 |

| Operating weight (kg) | 1790 |

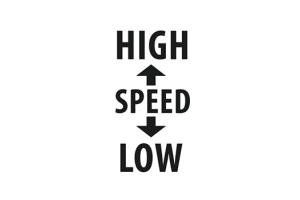

| Drive speed low (km/h) | 0-9 |

| Drive speed high (km/h) | 0-19 |

| Pulling force high (kg) | 800 |

| Pulling force low (kg) | 1550 |

| Hydraulic System | |

|---|---|

| Working Hydraulics (l/min) | (18+32) 50 |

| System pressure (bar) | 240 |

| Drivetrain hydraulics (l/min) | 85 |

| Drivetrain max system pressure (bar) | 370 |

| Cycle Times | |

|---|---|

| Raising boom (s) | 4.2 |

| Lowering boom (s) | 2.6 |

| Folding in bucket (s) | 2.9 |

| Tipping bucket (s) | 2.2 |

| Steering wheel rotations (L/R rev) | 4/5 |

Norcar Drive Systems

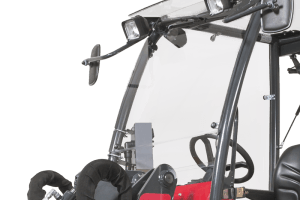

With the hand throttle, the engine’s RPM can be adjusted to suit the given application and to the needs of any hydraulic equipment.

Operation is soft and seamless when using the two separate pedals for driving forward or backward. The pedals are operated with the right foot, and they offer a relaxing and ergonomic driving position.

The EasyDrive system is well-suited to situations in which there are a great number of users, e.g., for rentals, in stables and for private users. Operators quickly get used to handllng the loader in a safe and efficient manner with the EasyDrive system.

The engine’s RPM is governed by a gas pedal operated with your right foot. With the ProDrive system, the engine’s RPM can also be adjusted by means of a hand throttle, allowing for an efficient use of hydraulic equipment, such as lawn mowers.

The direction of travel and speed are adjusted softly and seamlessly with the left foot pedal without you needing to move your foot. The machine is operated simply by pressing the pedal forward or backard for driving, while the loader remains stationary when the pedal is in the middle position.

One great advantage of the ProDrive system is the ability to use the foot throttle in order quickly to adjust the engine’s RPM for faster lifting and for more power, or else for calm and silent driving when the power is not needed. The ProDrive system is well-suited for work requiring a high degree of precision, e.g., working on green areas, stone paving and demolition work.

The direction of travel is selected by a button on the loader’s control stick.

With the Automotive drive system, the engine’s RPM can also be adjusted by a hand gas throttle, allowing for an efficient use of hydraulic equipment, such as lawn mowers.

The loader’s driving speed and the engine’s RPM are regulated by a gas pedal operated with the right foot.

At your left foot, there is a combined brake and clutch that allows you manually to reduce the driving speed, even at a high RPM, e.g., during loading work or when using equipment requiring a high engine RPM.

The drive system is easy to run and is excellent for loading, as well as for more continuous driving along roads and streets. Operating the system can be likened to driving a car with an automatic transmission.

Standard equipment

- Roll bar ROPS/FOPS, seatbelt

- Working lights, front

- Electrically maneuvered parking brake/safety system

- Float on the lifting boom

- Hand throttle/Foot throttle

- Engine speed and hour meter, engine heat and fuel level gauges

- Suspension seat with armrest

- Adjustable steering column

- ProDrive

Optional Extras

Tires

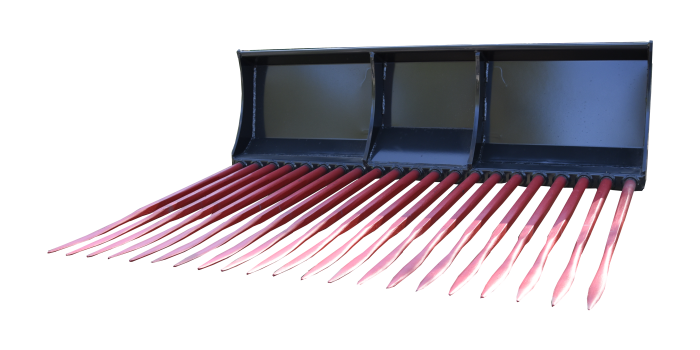

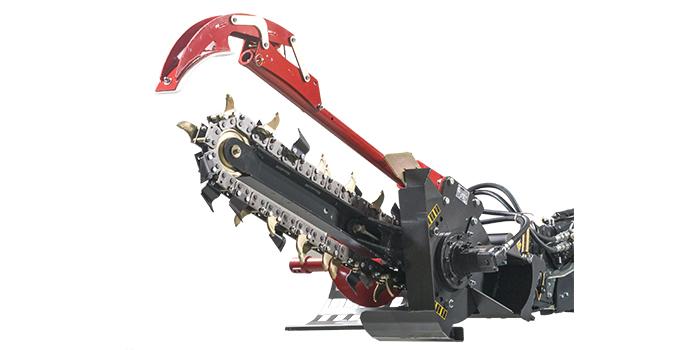

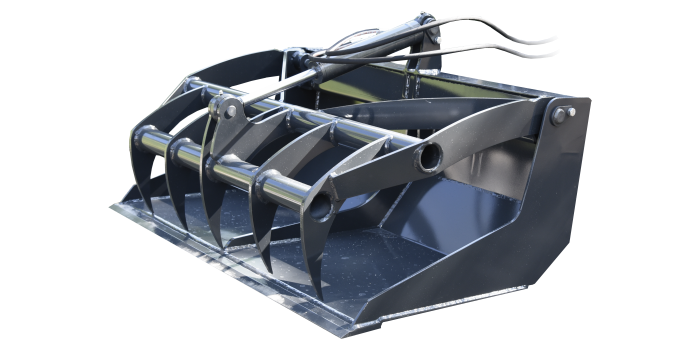

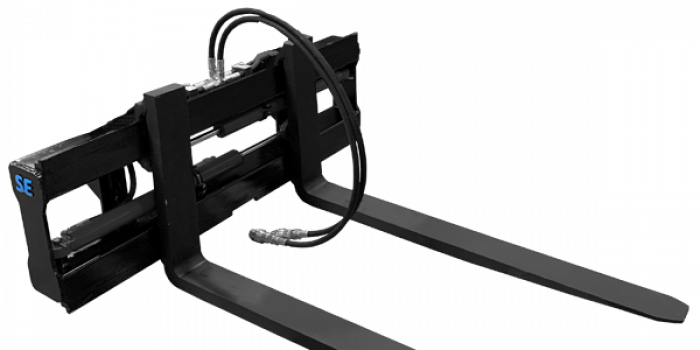

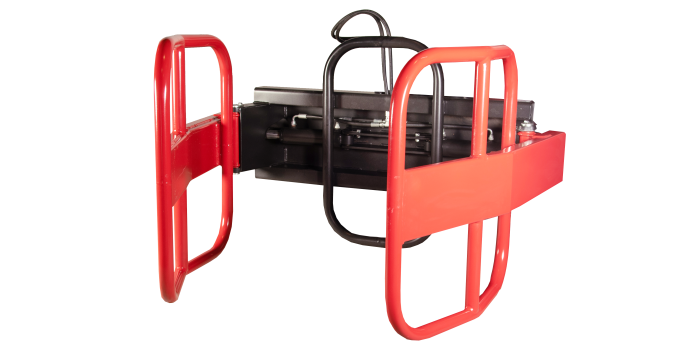

Tools - V. Compatible